Mold Tooling Transfer 101: Defining the Problem

With the events of 2020 exposing cracks and weaknesses in many supply chains, many companies are conducting mold tooling transfers to mitigate risk. If you have wondered if it’s time to transfer to a new supplier, maybe some of the following statements apply to you:

- I may need to establish a domestic supplier for my injection molding.

- I should probably move my injection mold tooling to a more stable supplier.

- My current injection molder may be a weak link in my supply chain.

- I feel like I’m just buying parts; not solutions to solve problems or take advantage of new opportunities.

- It seems like my business is no longer a priority to my injection molding supplier.

If you answered “Yes” to any of these, it may be time to look for a new injection molding supplier.

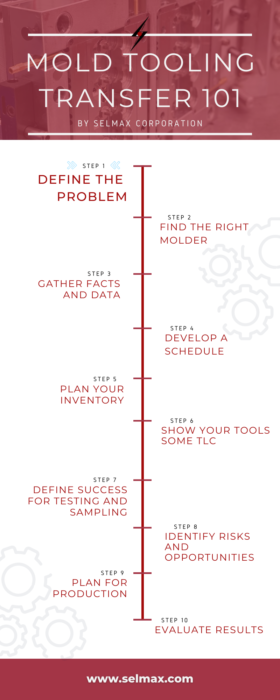

Transferring your injection mold tooling to a new supplier can seem like a daunting task. We will be breaking it down step-by-step over the next few weeks to help simplify the process.

Check Your Pulse

When considering a mold tooling transfer, it’s important to get a good understanding of your current situation. The following are some questions to consider:

→ What is the overall “health” of your current molder?

→ When was the last time you had a good status meeting with your molder?

→ Where are your tools?

→ Do you actually own the tools?

→ What condition are your tools in?

These are all important things to consider as you evaluate your current part production situation.

The location of your molder may be a risk in itself. In 2020, global supply chains felt the pain of the worldwide pandemic. Many businesses chose to bring their molds and production closer to home in order to keep their supply chains moving as smoothly as possible.

Assess Risks

If you are considering transferring your molds —especially from a molder in another country — there are some important things to keep in mind in the earliest stages of the process.

- Wait to tell your current molder of your plans to move the mold. Some molders may lose the incentive to act in your best interest after learning that they will be losing your business. It is better to have everything in place at the new supplier before notifying your current molder.

- Build inventory with your current molder. This will ensure you have enough inventory to keep up with sales throughout the transfer process.

- Gather information about the mold, such as the 3D files for the mold’s design, injection parameters, type of plastic used, and any other information that will be helpful for your new supplier to get your project set up and running smoothly.

Mold Tooling Transfers with Selmax

As a full-service plastic injection molder, Selmax stands ready to assist you in the process of sourcing your plastic injection molding in the United States.

We have manufactured millions of American-made products since 1971 and are proud to provide our customers with the high-level attention of a small operation and the quality and capability of a large-scale operation. Our turnkey manufacturing solutions include part design, mold design, mold making, high and low volume parts manufacturing, assembly, and delivery.

To learn more about transferring your mold tooling to Selmax, contact us today!

More in this series:

Step 2: Finding the Right Molder

Step 3: Gathering Facts and Data

Step 5: Planning Your Inventory

Step 6: Showing Your Tools Some TLC

Step 7: Defining Success for Testing and Sampling

Step 8: Identifying Risks and Opportunities

Step 9: Planning for Production

Step 10: Evaluating Results

3 Comments

Mold Tooling Transfer 101: Showing Your Tools Some TLC - Selmax Corporation

[…] Step 1: Defining the Problem […]

Mold Tooling Transfer 101: Defining Mold Testing Success - Selmax Corporation

[…] Step 1: Defining the Problem […]

Mold Tooling Transfer 101: Identifying Risks & Opportunities - Selmax Corporation

[…] Step 1: Defining the Problem […]